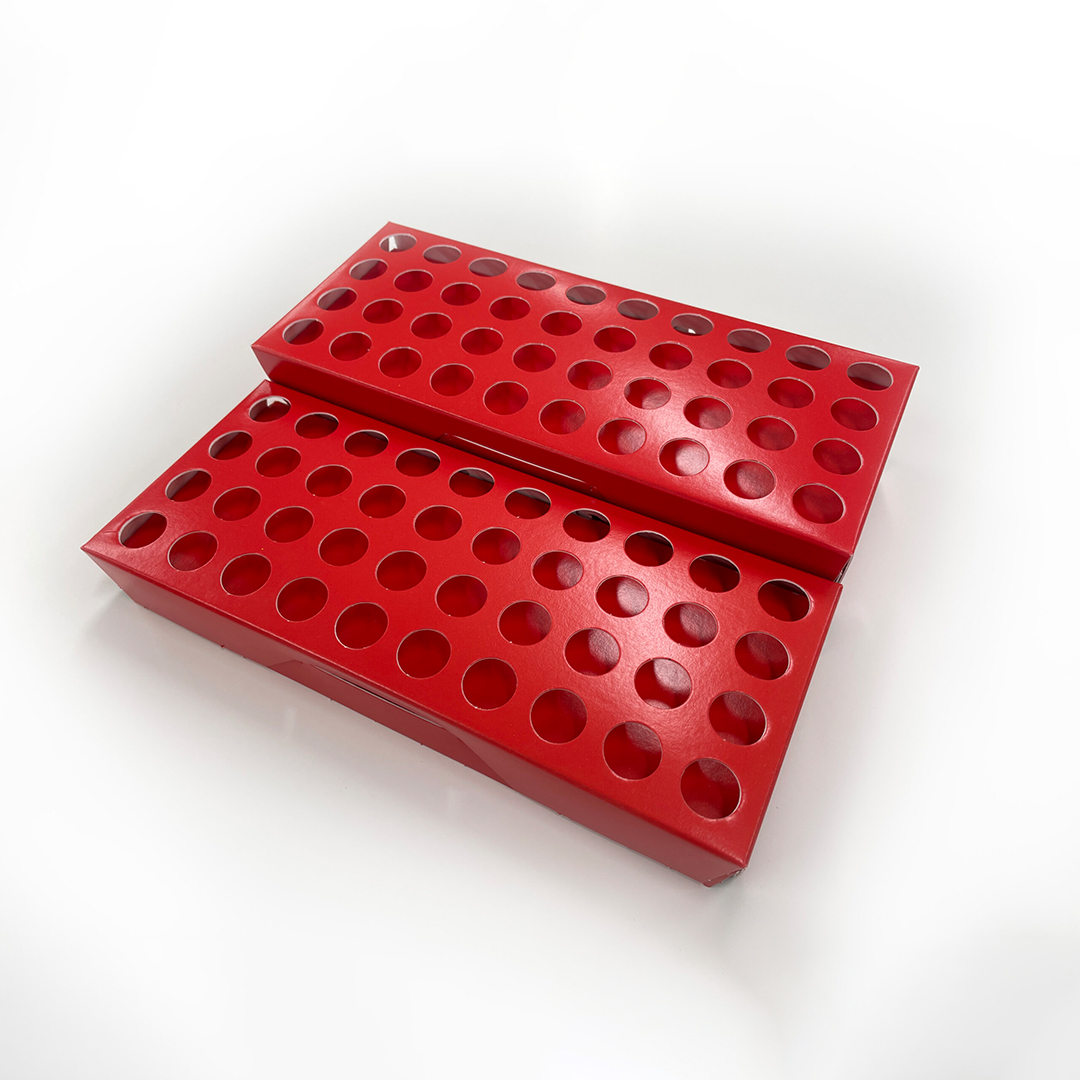

Description

Carton Inserts That Improve Fit And In-Box Safety

Carton inserts help brands protect products inside folding cartons by reducing movement and improving internal alignment. Many packaging teams use Custom Paperboard Inserts to keep lightweight and midweight items positioned cleanly across retail and shipping cycles. These inserts support cosmetics, small electronics, jars, bottles, and multi-piece kits with organized spacing. The structure keeps the outer carton from taking all the pressure during handling. This helps reduce scuffs, dents, and product-to-product contact.

Carton inserts bulk planning also supports brands that want consistent internal layouts across repeated SKUs. The same style can be adjusted for height, depth, and cavity shape while keeping packing routines familiar. This improves accuracy for teams handling multi-variant lines. It also helps maintain a tidy shelf appearance where product sets must look uniform. The overall setup improves both protection and presentation.

How Carton Inserts Support Safer Product Handling

Well-fitted inserts create a stable product cavity that holds items in place during storage and transit. This reduces rattling and edge impact inside the carton. Inserts also help distribute pressure across the box footprint rather than concentrating it on one corner. This matters for fragile caps, delicate glass edges, and printed label faces. The result is a cleaner arrival condition for retail and delivery orders.

For brands that ship subscription kits, inserts also help maintain the same customer experience across every dispatch. Products remain aligned in a predictable order. This supports easier quality checks before sealing cartons. The internal structure can be designed for single items or layered sets. This keeps the in-box layout neat without extra filler.

In-Box Protection Advantages

- Improves product stability inside cartons

- Reduces surface contact between packed items

- Supports clean and repeatable packing layouts

- Helps limit internal movement during transit

Packing And Storage Highlights

- Supports consistent insert layouts across SKUs

- Reduces damage risk for fragile product parts

- Improves organization for multi-piece kits

- Helps maintain a tidy retail-ready finish

| Feature focus | Description | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Fit control | Custom cavities to reduce movement | Paperboard, kraft board | Smooth, matte, gloss | Multi-cavity designs | Cosmetics and jars |

| Layer support | Organized spacing for sets | SBS, recycled board | Anti-scuff options | Stackable levels | Subscription kits |

| Structure stability | Inner strength without extra bulk | Thick paperboard grades | Clean printable faces | Reinforced partitions | Retail cartons |

Cardboard Inserts For Packaging In Retail Sets

Brands often select carton inserts when they want internal separation for bundled items and multi-variant product lines. Many product lines align this need with Custom Product Options to maintain safety for items that sit close together inside a single carton. This helps reduce abrasion between components like bottles, droppers, caps, and accessories. Inserts also make it easier to keep an organized product story inside the box. The layout supports cleaner presentation for premium and everyday retail ranges.

Carton inserts also work well for Custom box inserts that need consistent cavities for different product shapes. Small changes in cavity depth and divider placement can support multiple sizes without breaking the overall insert style. This helps teams maintain one packaging family across a wider catalog. It also reduces packing confusion during high-volume runs. The end result is a more stable and predictable internal setup.

How Inserts Improve Arrangement For Multi-Item Boxes

A structured insert helps keep each component in its own space. This reduces the chance of scratches or pressure marks that can happen when items touch during movement. The layout also improves the customer’s first look inside the carton. Products are easier to identify and remove without disturbing other parts. This supports a calmer unboxing routine.

For brands offering seasonal kits, inserts can also be swapped or adjusted without changing the outer carton size. This helps refresh product combinations quickly. The same approach supports gift-ready ranges where internal order matters. It also helps reduce the reliance on extra void fill. The internal structure does most of the organizing work.

Retail Arrangement Benefits

- Keeps bundled items separated and aligned

- Supports clean internal presentation for sets

- Helps reduce handling wear inside cartons

- Improves product identification during unboxing

Kit And Variant Support Points

- Helps manage multi-item carton layouts

- Supports consistent bundle presentation

- Reduces internal clutter in gift sets

- Helps maintain repeatable packing flow

| Feature focus | Description | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Divider layouts | Separation for multi-part kits | Paperboard, kraft | Smooth, matte | Cross partitions | Gift sets |

| Cavity design | Secure hold for varied shapes | SBS, recycled board | Clean printable faces | Custom cut-outs | Beauty and tools |

| Assembly ease | Quick insert folding and placement | Lightweight board options | Low-scuff surfaces | Pre-creased lines | High-volume packing |

Carton Inserts Bulk Solutions For Shipping Lines

Carton inserts bulk orders support brands that need high-output packaging with steady internal protection. Many manufacturers coordinate these programs through Packaging Inserts Wholesale to keep insert sizing, board selection, and cavity layouts consistent across multiple product categories. This is useful for brands managing both retail and e-commerce channels. Inserts help reduce product shift inside cartons during courier handling. The structure keeps heavier items from pressing into lighter accessories.

These inserts can also support Corrugated cardboard inserts where extra cushioning and structural strength are needed. The inner architecture can be adjusted for thicker walls or layered reinforcement. This supports safer storage for stockrooms and dispatch lines. It also helps reduce edge crushing during stacked transport. The internal setup improves the overall carton performance without making the outer box complicated.

How Shipping Inserts Reduce Transit-Related Damage

A well-designed insert stabilizes the product center of gravity inside the carton. This helps reduce sudden impact transfer to delicate edges. Inserts also limit friction across printed or coated product surfaces. This matters for products with glossy labels or sensitive finishes. A cleaner interior hold often results in fewer customer complaints linked to in-box scuffs.

For brands shipping nationwide, stable insert dimensions also help standardize pack-out steps. Teams can follow the same packing order across warehouses. This reduces the risk of mispacking. The approach supports more predictable delivery outcomes for bulk orders. It also helps maintain consistent internal visuals when customers open the pack.

Transit Protection Benefits

- Reduces product shift during shipping

- Helps distribute internal pressure evenly

- Supports safer stacking in outer cartons

- Lowers the need for extra filler

Bulk Operations Highlights

- Supports repeatable packing for large runs

- Helps reduce returns linked to in-box damage

- Improves warehouse organization for inserts

- Keeps dispatch routines faster and cleaner

| Feature focus | Description | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Heavy-item support | Stronger internal bracing | Corrugated, thick paperboard | Clean, low-scuff | Reinforced walls | Electronics and bottles |

| Multi-zone layout | Separate cavities for mixed SKUs | SBS, kraft | Matte, smooth | Layered platforms | Subscription shipping |

| Stack stability | Improved internal load control | Corrugated blends | Anti-scuff options | Edge buffers | Bulk dispatch |

Cardboard Inserts For Mailers And Retail Hybrids

Brands also use inserts for mailer-style cartons where product security must stay strong during movement. These internal supports help reduce friction and impact in tight shipping formats. They are useful for Cardboard inserts for mailers that carry small technology items, wellness products, and compact lifestyle goods. Inserts keep the product centered and reduce corner contact with the outer shell. This helps maintain a cleaner arrival condition.

For specialized uses, some brands also develop Cardboard Inserts for bags where inserts stabilize boxed pouches or structured product sleeves inside a larger pack. The same engineering approach supports consistent internal spacing across mixed-material packaging. This helps reduce shifting when multiple items are packed together. The internal structure keeps things aligned while maintaining a tidy outer presentation.

How Inserts Adapt To Mixed Packaging Systems

Inserts can be designed as single-piece cradles or multi-part partitions depending on the product. This helps brands adapt one insert family across mailers, folding cartons, and hybrid kits. The internal layout can also include finger notches for easier removal. This improves the customer handling experience. The structure supports both protection and ease of use.

For brands that rotate product bundles seasonally, insert updates can be done without changing outer packaging dimensions. This supports fast packaging refresh cycles. It also helps reduce waste from redesigning entire box families. The result is a more flexible packaging plan. The inner structure carries the main protective role.

Mailer And Hybrid Benefits

- Supports centered product hold in mailers

- Helps reduce friction against outer walls

- Improves removal comfort for customers

- Works for mixed-format product bundles

Flexibility And Design Highlights

- Supports insert reuse across packaging families

- Helps brands refresh kits with fewer structural changes

- Improves internal organization for compact packs

- Maintains cleaner product presentation on opening

| Feature focus | Description | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Compact support | Secure hold for small-format mailers | Paperboard, corrugated | Smooth, matte | Finger notches | Mailer kits |

| Hybrid layouts | Internal spacing for mixed items | SBS, kraft | Clean printable faces | Multi-part inserts | Retail + shipping |

| Brand alignment | Insert designs matched to outer theme | Recycled board | Low-scuff | Custom die-cuts | Lifestyle products |