Description

Custom product packaging inserts for safe item placement

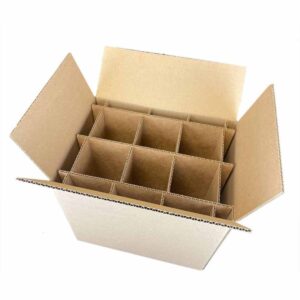

Product Packaging Inserts help brands keep items stable inside boxes during shipping, storage, and retail handling. Many businesses rely on Corrugated Inserts when they need structured strength for heavier items and consistent in-box separation. These inserts support electronics, cosmetics, glass items, subscription kits, and multi-part accessories with a cleaner, more controlled layout. The design reduces shifting that can cause scratches, dents, or corner pressure. This helps brands maintain a reliable unboxing standard.

We at Inserts Hub offer Product Packaging Inserts at wholesale prices with custom sizes, die lines, and material options for small runs and larger production cycles. The right insert structure also helps reduce filler usage while keeping box interiors tidy and repeatable across SKUs. Brands can align insert shapes with product silhouettes for smoother packing speed. This improves consistency for high-volume dispatch routines. The result is a more organized packaging system that supports daily operations.

Insert structure that reduces movement in transit

A well-planned insert layout creates stable contact points that hold products in a predictable position. This is especially helpful when the outer box travels long distances with repeated handling across hubs. Corrugated designs can be tuned for depth and flute direction to manage compression and vibration stress. The internal fit also helps keep labels, accessories, and manuals aligned within the same kit. This supports cleaner presentation across the full pack.

Insert design also improves quality control during assembly and packing. Staff can identify correct product placement faster when cavities and slots are clearly defined. This reduces packing errors for bundles that include multiple components. Over time, fewer returns and fewer damaged units protect brand trust. A strong internal structure often becomes a key part of overall packaging performance.

Key Insert Performance Benefits

- Holds products in fixed positions

- Helps reduce surface scuffs and edge pressure

- Supports multi-part kits with clean separation

- Improves in-box presentation consistency

Operational And Branding Gains

- Reduces product shifting in courier handling

- Helps standardize packing for multi-SKU lines

- Improves quality checks for bundled items

- Supports cleaner unboxing experience

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Fit accuracy | Custom cavities matched to product shapes | Corrugated, SBS, Kraft, recycled board | Matte, gloss, spot UV | Slots, cut-outs, spacers | Electronics and accessories |

| Impact control | Reduces movement and contact abrasion | E-flute, B-flute, mixed flutes | Anti-scuff coatings | Corner buffers | Glass and skincare |

| Pack efficiency | Supports faster and cleaner assembly | Light to rigid board grades | Smooth lamination | Fold locks | Subscription kits |

| Visual order | Keeps manuals and add-ons aligned | Paperboard + corrugated combos | PMS/CMYK-friendly | Card pockets | Retail bundles |

Best product packaging inserts for retail kits

Product Packaging Inserts also help brands maintain a clean shelf-ready interior layout for gift sets, launches, and coordinated retail ranges. Many sellers use Protective Box Inserts when they want a broader insert family for cosmetics, lifestyle items, and multi-compartment cartons. This improves product spacing and keeps the box interior looking tidy even after repeated store handling. A consistent insert theme can also simplify expansion into new sizes. This supports better range control for growing brands.

These inserts can be tailored to support packaging inserts ideas like layered compartments, product-and-accessory pairing, or dual-level trays for premium bundles. The structure helps keep product orientation consistent across units, which makes restocking easier for retail staff. Clear cavities also help customers understand what is included in a kit at a glance. This reduces confusion during purchase decisions. The outcome is a more organized, more trust-building presentation.

Packaging insert cards and layout clarity

Brands often pair structural inserts with packaging insert cards to guide customers through usage, care, or next-purchase suggestions. Insert slots can be designed to hold cards without bending or sliding. This keeps the inside of the box clean and easy to navigate. For trial sets and sample kits, this adds clarity without increasing bulk. It also helps maintain a consistent brand voice across products.

A stable interior layout supports product insert card design by providing consistent placement points. This is useful when brands want every unit to feel the same across large runs. Retailers benefit because they can verify completeness quickly during stocking. Customers benefit because the unboxing flow feels intentional and organized. The insert becomes part of the brand experience rather than an afterthought.

Retail And Kit Presentation Benefits

- Supports clean compartmented layouts

- Helps keep bundles visually organized

- Improves card placement and readability

- Reduces product mix-ups in sets

Merchandising And Range Support

- Helps standardize gift and launch kits

- Supports repeatable interior layouts across sizes

- Improves shelf confidence for premium bundles

- Helps reduce returns caused by missing parts

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Kit organization | Multi-compartment layouts for coordinated sets | SBS, Kraft, corrugated | Matte, gloss | Dividers, insert walls | Gift and seasonal kits |

| Card integration | Built-in pockets or slots for info cards | Paperboard blends | Smooth lamination | Card holders | Subscription and samples |

| Visual balance | Keeps items evenly spaced and aligned | Rigid-enhanced boards | Spot UV accents | Layered trays | Premium retail |

| SKU flexibility | Scales insert shapes across variants | Mixed board grades | PMS/CMYK-ready | Modular cavities | Multi-SKU ranges |

Product insert card design for strong brand recall

Product Packaging Inserts can also support brand storytelling by organizing how customers discover items inside the box. Many businesses rely on Inserts Hub when they need a structured insert plan that aligns with multiple box styles and long-term catalog growth. The right insert layout helps brands stage items in a deliberate order, especially for kits that include primary products and smaller add-ons. This supports a smoother, more guided unboxing flow. It also helps brands keep internal layouts consistent across reorders.

Custom packaging inserts can be designed to work with mailers, folding cartons, rigid boxes, and retail sets without sacrificing speed of assembly. This is useful for brands that want a single design language across categories. Inserts can also be optimized to reduce extra void fill. This keeps packaging cleaner and more efficient. The result is stronger in-box control with better brand consistency.

Corrugated box inserts for heavier products

Corrugated Box inserts are often chosen when product weight or fragility requires stronger shock control. The flute structure helps absorb impact and manage stacking pressure during shipping. This is important for electronics, glass items, and multi-part hardware kits. A well-sized corrugated insert also helps keep products from sliding into corners. This improves both protection and presentation.

Brands can also use layered corrugated formats to create step-by-step reveal sequences for premium kits. This supports both functional protection and brand-led unboxing design. The material remains compatible with clean printing and labeling on selected surfaces. This allows brands to add simple guidance icons or part identifiers. The insert becomes both a protector and an organizer.

Protection And Experience Benefits

- Supports heavier items with stable structure

- Helps reduce corner impact inside boxes

- Works well with layered unboxing formats

- Keeps accessories aligned with main products

Shipping And Assembly Advantages

- Improves protection for fragile components

- Helps reduce filler use and in-box clutter

- Supports consistent packing for larger runs

- Maintains clean interior presentation

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Weight support | Strong internal bracing for heavier items | E/B-flute corrugated, double-wall | Matte, smooth coatings | Reinforced ribs | Electronics, tools |

| Vibration control | Reduces micro-movement in long transit | Corrugated + paperboard combos | Anti-scuff | Lock tabs | Nationwide shipping |

| Modular layouts | Separate parts in multi-component sets | Mixed board systems | PMS/CMYK-ready | Divider grids | Hardware and kits |

| Brand order | Guides item reveal sequence | Corrugated layers | Spot UV accents | Tiered trays | Premium bundles |