Description

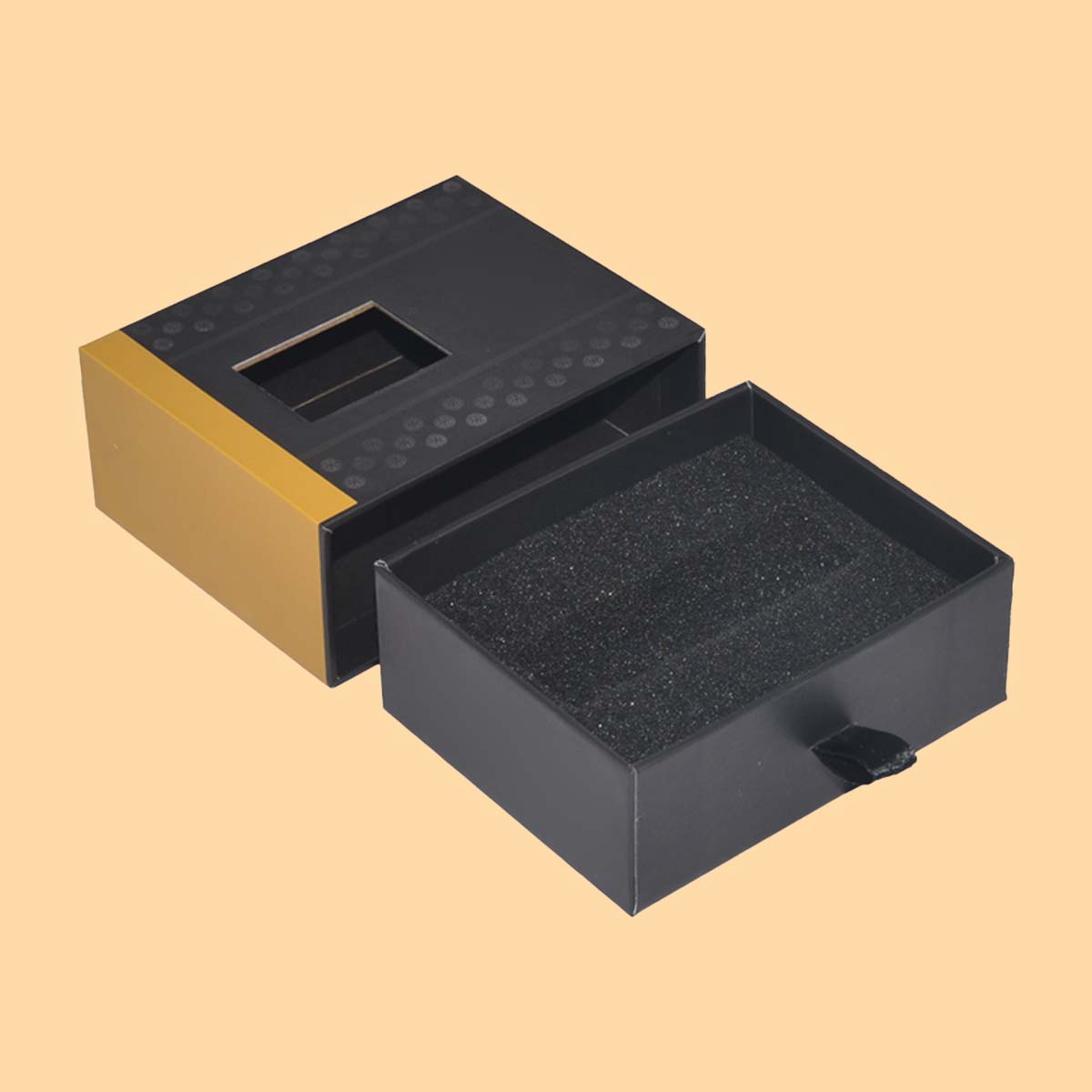

Cardboard inserts for packaging that protect goods

Corrugated Inserts give brands a reliable way to organize, separate, and cushion products inside shipping and retail boxes. Many teams pair them with Mini Cupcake Inserts when they want consistent in-box control across bakery, gifting, and multi-item assortments. This format supports Cardboard inserts for mailers, larger master cartons, and mixed SKU bundles with less shifting during transit. The structure helps reduce corner rub, surface dents, and loose presentation at unboxing. It also keeps pack-outs cleaner for fast-moving orders.

These Packaging inserts work for cosmetics, electronics accessories, food items with secondary packing needs, candles, jars, and subscription kits. You can develop slots, partitions, and layered layouts that match fragile shapes without adding excess filler. For brands that ship repeatedly, the repeatable fit helps maintain a steady presentation across reorders. The result is better product stability with a simple, practical insert system.

How corrugated inserts reduce product movement

Corrugated layers create controlled spacing that helps prevent product-to-product contact inside a carton. This is useful for bundles that include glass, metal, or mixed material items where friction can damage labels or finishes. The insert structure also helps distribute load when boxes are stacked in storage and shipping. That reduces pressure points on delicate items. It also supports more predictable handling in warehouses.

For e-commerce, tighter insert tolerances help reduce void space without forcing brands into oversized outer boxes. This can improve dimensional efficiency and support cleaner packing lines. When products arrive with the same orderly layout, customers feel more confidence in the brand’s shipping care. The same approach benefits retail kits where presentation influences buying decisions. The insert becomes part of the product story without needing heavy design claims.

Product Stability Gains

- Keeps items aligned during long-distance shipping

- Reduces surface contact between packed products

- Supports tidy arrangement for multi-item kits

- Improves unboxing consistency across batches

Packing Workflow Support

- Helps speed up pick-and-pack routines

- Reduces reliance on loose void fillers

- Supports cleaner barcode and label visibility

- Improves carton stacking confidence in storage

| Feature focus | Description | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Structural control | Slot and partition layouts to lock product positions | E-flute, B-flute, C-flute | Natural kraft, white top | Die-cut channels | Multi-SKU bundles |

| Mailer compatibility | Shaped fits for compact shipping | Micro-flute, E-flute | Smooth stock options | Folded rails | Cardboard inserts for mailers |

| Bag and kit support | Flat stiffeners and layered separators | Lightweight corrugated | Minimal finish | Edge guards | Cardboard Inserts for bags |

| Load distribution | Helps reduce pressure on fragile items | Heavy duty corrugated inserts | Clean kraft face | Reinforced ribs | Electronics and glass |

Wholesale corrugated inserts for growing brands

Corrugated insert systems help expanding brands maintain consistent in-box protection across multiple product lines and shipping zones. Many packaging teams align sourcing through Wholesale Product Solutions to keep insert grades, dielines, and size families consistent as new SKUs join the same outer box system. This supports predictable performance for monthly subscriptions, seasonal bundles, and retail-ready sets. It also reduces last-minute packaging variations that can disrupt warehouse flow. The structure remains easy to store flat and assemble quickly.

Wholesale corrugated inserts also allow brands to standardize thickness and flute choices based on product weight. Lighter inserts work well for cosmetics and accessories, while heavier builds suit hardware, glass sets, and multi-layer kits. For teams managing multiple fulfillment points, consistent insert footprints simplify training and packing accuracy. This keeps shipping outcomes more uniform across regions. The overall approach supports smarter scaling.

Handling benefits for high volume packing teams

Bulk insert planning helps operations teams maintain steady packing speed during high-demand cycles. Insert bundles can be delivered flat, labeled by size family, and deployed across stations without complex sorting. This reduces assembly errors when orders include mixed product types. The repeated fit also helps staff pack confidently without testing placement each time. That keeps throughput steady during promotional peaks.

For retail distribution, consistent insert geometry helps protect goods during pallet movement and store-level restocking. The structure reduces vibration-related wear on surfaces and corners. This supports cleaner shelf presentation as outer cartons are opened and items are displayed. Brands with multiple variants benefit from a predictable inner layout. The same layout also supports easier quality control during audits.

Bulk Order Advantages

- Keeps size families consistent across reorders

- Supports faster station-level insert deployment

- Helps reduce packing mistakes in mixed kits

- Improves protection for long transit routes

Scaling Performance Points

- Helps unify insert specs across warehouses

- Supports stable outcomes for subscription programs

- Reduces damage-related returns over time

- Improves layout consistency for retail sets

| Feature focus | Description | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Volume readiness | Repeatable dielines for large runs | E-flute, B-flute | Kraft, white-faced | Size-coded bundles | National distribution |

| Multi-variant control | One system for different SKUs | Mixed flute sets | Clean stock | Modular partitions | Subscription kits |

| Storage efficiency | Flat-packed for warehouse control | Lightweight corrugated | Natural finish | Easy-fold scoring | Fulfillment centers |

| Heavy load support | Strong builds for weighty goods | Heavy duty corrugated inserts | Reinforced faces | Double-wall options | Industrial accessories |

Large corrugated inserts for heavy duty support

Large corrugated inserts help brands protect bigger items and multi-layer bundles that need strong internal separation. Many businesses build these systems with custom packaging inserts to maintain consistent insert architecture across electronics, appliances, glass sets, and high-value accessories. The larger footprint allows deeper channels, stronger ribs, and more controlled spacing. This helps prevent item sway inside wider cartons. It also supports safer stacking in storage and long-haul shipping.

These formats suit brands that require Cardboard inserts for packaging with higher load control and durable corner performance. You can integrate layered trays, cross partitions, and custom cavities to handle varied shapes in one pack. For mixed kits, the insert can separate fragile and solid items without adding extra outer packaging. This helps brands reduce material clutter while improving inner organization. The result is cleaner protection for larger carton systems.

Printing and sizing for organized packaging inserts

Insert sizing is most effective when matched to product weight, shape, and the outer box’s internal clearance. This helps reduce micro-movement that can cause scuffs or stress on edges. Brands shipping high-value goods often add simple print cues for orientation, batch handling, or station-level guidance. These marks can improve packing accuracy without turning the insert into a decorative piece. The focus stays on function and fit.

For brands that ship globally, consistent sizing standards also help with documentation and packing SOPs. Inserts can be grouped by size families that align with outer carton ranges. This creates a more predictable procurement plan and reduces last-minute die changes. It also supports cleaner training across new fulfillment hires. Over time, this reduces operational noise.

Heavy Load Protection Benefits

- Supports broader cartons with stable inner control

- Helps reduce sway for larger or layered items

- Improves stacking confidence in storage

- Keeps mixed kits more orderly at unboxing

Operational Safety Highlights

- Helps protect high-value items during long routes

- Supports standardized size families across SKUs

- Reduces pressure points inside large cartons

- Improves quality control for bulk dispatch

| Feature focus | Description | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Large-format stability | Wider partitions for bigger products | B-flute, C-flute | Kraft, white liner | Cross-lock ribs | Appliances and kits |

| Multi-layer layouts | Stacked trays for mixed assortments | Double-wall corrugated | Clean stock | Interlocking layers | High-value bundles |

| Bag reinforcement | Flat stiffeners for carry formats | E-flute sheets | Natural finish | Rounded corners | Cardboard Inserts for bags |

| Shipping endurance | Strong internal bracing | Heavy duty corrugated inserts | Reinforced faces | Edge guards | Long-distance logistics |