Description

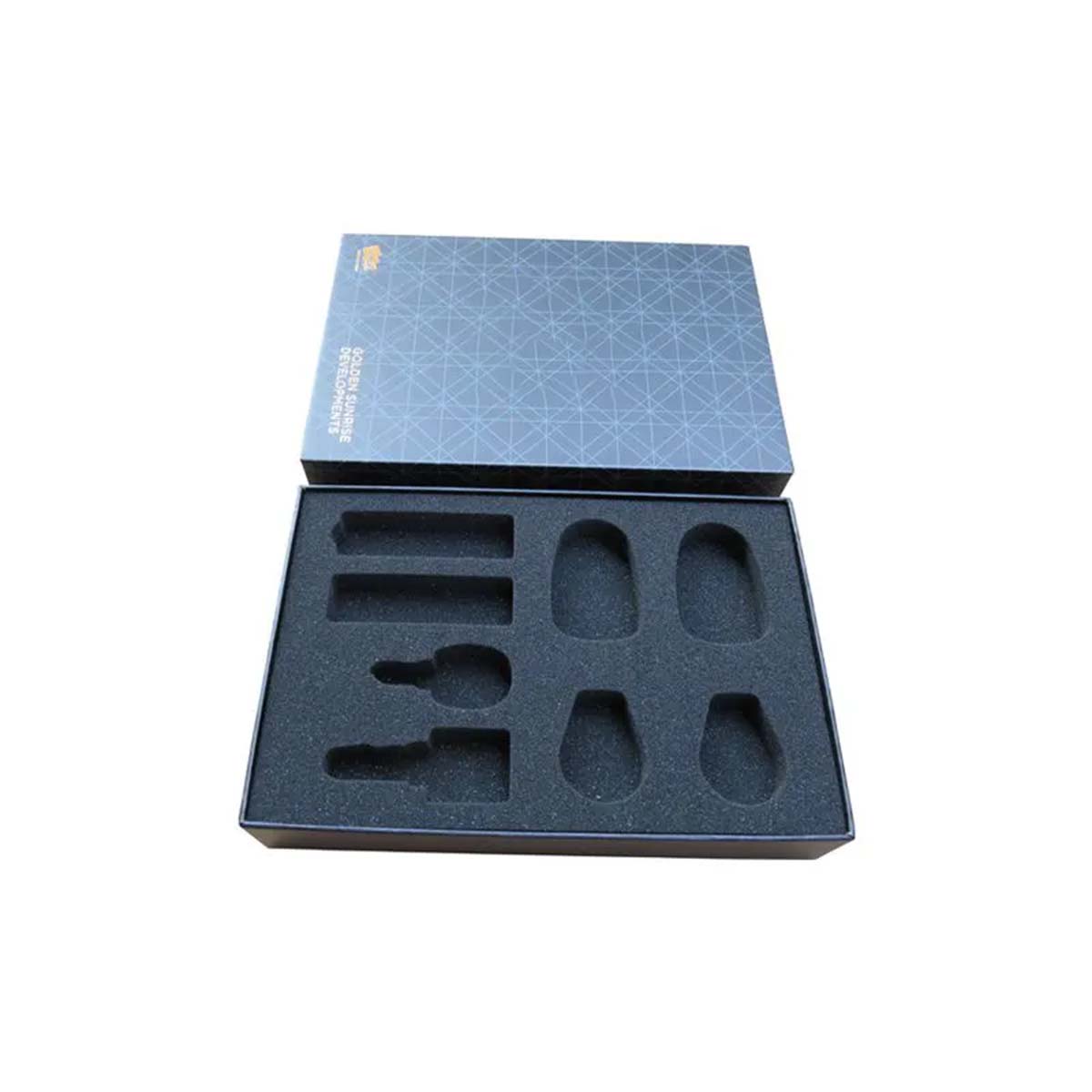

Custom Boxes With Foam Inserts For Safe Product Fit

Custom Boxes With Foam Inserts help brands secure delicate items with clean presentation and controlled in-box movement for retail and shipping. Many teams pair this format with Foam Inserts For Gift Boxes when they want the same protection logic across gifting, electronics, and premium bundle lines. The foam cutouts hold products in place and reduce friction marks during handling. This supports safer unboxing and a more organized layout for customers. The structure works well for short runs and expanding SKUs.

These boxes support tech accessories, cosmetics, glass items, tools, and collector products where damage risk needs tighter control. The outer box can be styled in multiple materials and finishes while the foam interior is cut to match product contours. This helps reduce void space without making the pack heavy. The result is a dependable combination of outer branding and inner protection. It also supports Foam inserts for packaging needs across varied industries.

Foam Inserts For Packaging That Protect Fine Items

Foam interiors create a stable cradle that helps prevent scratches, corner knocks, and micro-movement during transit. This is useful when brands ship products with polished surfaces, fragile edges, or sensitive components. The inserts can be layered to separate accessories, manuals, and spare parts within the same pack. This keeps the contents neat when customers open the box. It also helps reduce returns linked to cosmetic damage.

Brands that want a more refined inner look can adjust foam density and surface texture without changing the box structure. This gives more control over how the product sits in the cavity and how it is revealed during unboxing. For premium lines, consistent insert fit can raise perceived care and product value. For everyday shipping, it improves packing reliability. This balance supports both retail-facing and e-commerce workflows.

Protection Highlights

- Keeps items centered inside the box

- Reduces surface rubbing and transit scuffs

- Supports multi-layer layouts for accessories

- Helps maintain a clean unboxing sequence

Handling And Display Advantages

- Improves stability for fragile or polished items

- Helps staff pack faster with pre-cut cavities

- Reduces in-box shifting during courier handling

- Supports clean shelf presentation for premium SKUs

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Inner fit accuracy | Cavities cut to product shape | EVA, EPE, PU foam | Smooth, textured | Layered trays | Electronics and beauty |

| Shock control | Helps absorb minor impact | Medium to high density foam | Optional fabric wrap | Corner buffers | Glass and fragile goods |

| Layout organization | Separates parts cleanly | Multi-layer foam sets | Clean-cut edges | Tooling slots | Kits and bundles |

| Outer branding | Supports consistent artwork | Rigid, corrugated, SBS | Matte, gloss, spot UV | Sleeves, labels | Retail lines |

Custom boxes with foam inserts wholesale for brands

Custom boxes with foam inserts bulk orders help businesses maintain consistent protection across mass production cycles and multi-variant product lines. Many packaging teams source supporting formats under Custom Product Options to align foam styles with other insert-led solutions for gift, retail, and shipping needs. Wholesale planning helps keep cavity tolerances stable across reorders. This improves layout predictability for packing teams and reduces product movement variance. It also supports cleaner brand consistency across collections.

When brands need Custom boxes with foam inserts cheap options without losing structure, foam density and board choices can be balanced to meet budget and performance goals. Inserts can be designed to reduce wasted material while still holding the product snugly. This makes bulk planning more efficient for growing brands. Over time, stable insert designs help reduce operational friction across warehouses. The result is smoother procurement and more reliable pack outcomes.

Custom Foam Inserts For Clean Retail Presentation

Custom foam inserts let brands control how a product sits, how it is revealed, and how accessories are placed around it. This supports retail categories where visual order influences buying confidence. The foam can be cut to match unique shapes, allowing brands to keep the outer box size compact. This helps reduce shipping volume while maintaining an organized visual layout. It also supports stronger product separation in combination packs.

For large-volume programs, consistent insert fit helps staff maintain faster pack-out speed with fewer adjustments. The same insert pattern can be reused across multiple sizes by adjusting cavity depth and spacing. This helps brands expand product families without redesigning the entire inner structure. It also supports better quality checks in long-run production. The overall process stays stable across repeated orders.

Wholesale Value Highlights

- Keeps insert fit consistent across batches

- Supports multi-SKU protection with one layout system

- Helps control per-unit costs in large runs

- Reduces packing errors with fixed cavities

Bulk Planning Advantages

- Supports repeatable inner designs for core SKUs

- Helps reduce returns tied to transit movement

- Improves warehouse packing rhythm for kits

- Keeps brand presentation steady across variants

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Bulk stability | Repeatable cavity sizing | EVA, EPE, PE foam | Clean-cut surfaces | Multi-layer sets | High-volume electronics |

| Cost control | Balanced foam density | Standard to premium foams | Optional wraps | Simplified layouts | Retail programs |

| Kit organization | Holds multiple components | Layered foam trays | Smooth edges | Accessory slots | Tools and devices |

| Brand alignment | Matches outer box families | Rigid, corrugated, folding board | Matte, gloss | Sleeves, labels | Collection-based lines |

Protective Foam Insert Packaging For Multi Item Kits

Foam insert packaging helps brands build orderly product kits where each component stays locked in position during movement. Many businesses develop these setups with custom packaging inserts when they need consistent foam cutting, stable layouts, and scalable styles for different box sizes. This approach supports retail bundles, subscription sets, and technical product kits. The inner structure keeps items separated and reduces pressure marks on delicate surfaces. It also helps maintain a tidy presentation for customers.

These packs are useful for products that ship with chargers, cables, manuals, or small accessories that should not float inside one compartment. The foam layers can be arranged to create clear zones for each piece. This improves both product safety and customer navigation during unboxing. It also supports stronger inventory accuracy when staff pack high-count orders. The format aligns well with Foam inserts for packaging across branded kit categories.

Styrofoam Packaging Inserts For Light Weight Safety

Styrofoam packaging inserts are often used when brands need lightweight cushioning for products that must stay stable without adding extra shipping weight. This can be relevant for certain electronics, display items, and fragile accessories where impact risk is moderate but movement control is still critical. The insert shape can be cut to secure multiple items in one layer. This keeps the kit clean and balanced at open. It also supports faster assembly for high-volume programs.

Brands can also mix insert types across product tiers, using lighter inserts for entry ranges and denser foam for premium lines. This helps manage cost while keeping protection aligned with product value. The outer box can remain consistent across the line with interior variations tuned to the contents. This supports a unified brand structure. The result is controlled protection without overbuilding the pack.

Kit Presentation Highlights

- Separates components into clear zones

- Helps prevent accessory-to-product contact

- Supports layered layouts for complex sets

- Keeps unboxing order simple and clean

Storage And Transit Advantages

- Supports tidy packing for multi-item bundles

- Helps reduce missing-part issues in fulfillment

- Improves stack stability for boxed kits

- Maintains product alignment during long routes

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Multi-item layout | Defined cavities for parts | EVA, EPE, styrofoam options | Smooth, textured | Layer separators | Electronics kits |

| Weight balance | Protects without heavy fillers | Light to medium density foams | Clean cut edges | Lift tabs | Subscription boxes |

| Unboxing flow | Guides customer through items | Layered trays | Optional wraps | Accessory labels | Premium bundles |

| Outer compatibility | Uses multiple box styles | Rigid, corrugated, folding cartons | Matte, gloss, spot UV | Sleeves | Retail and shipping |