Description

Custom Plastic Inserts For Retail Safety And Display

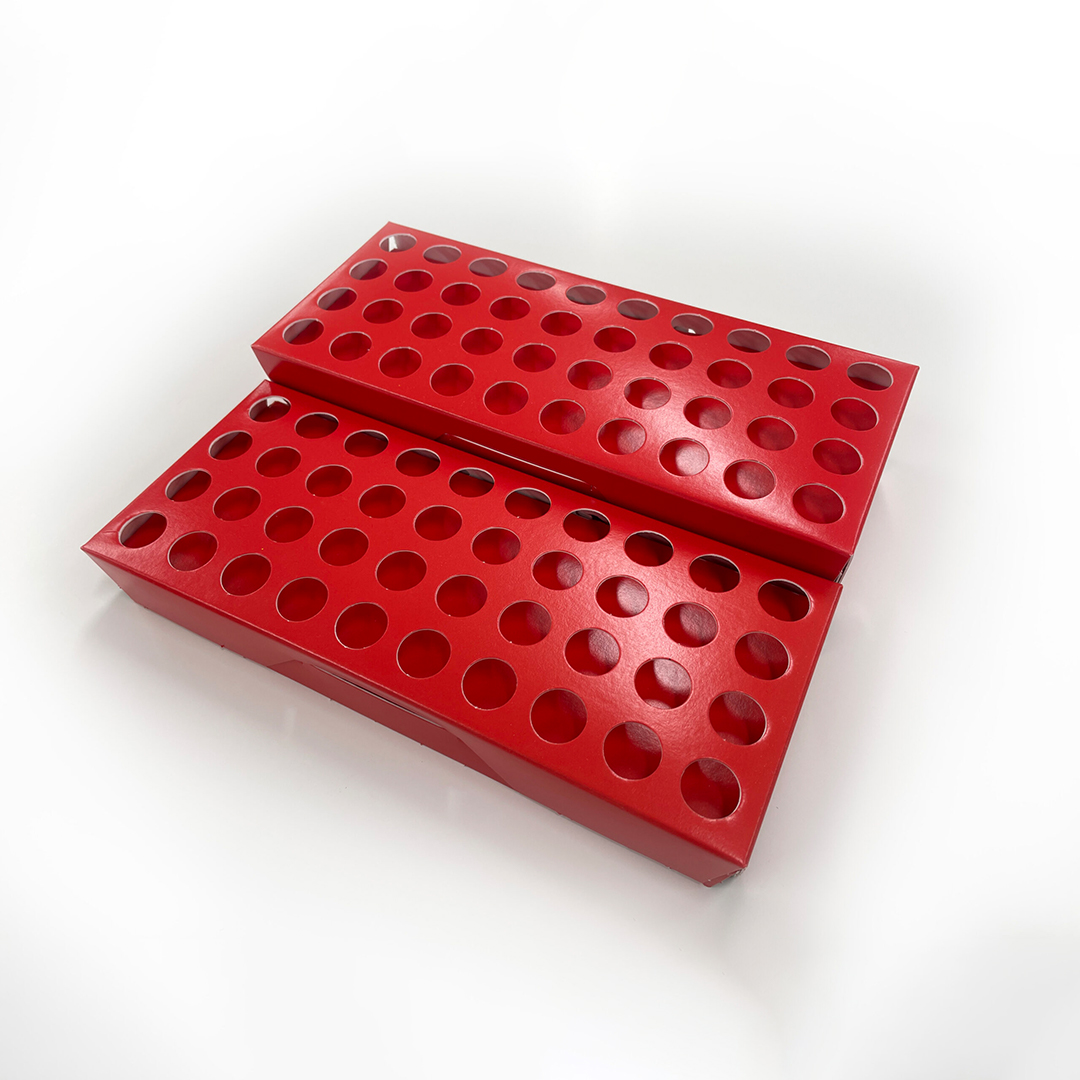

Custom plastic inserts help brands keep products stable, separated, and visually organized inside presentation and shipping boxes. Many product lines pair plastic trays with Corrugated Inserts when they want layered protection for heavier items while still keeping compartments clean and easy to identify. We at Inserts Hub offer Custom Plastic Inserts at wholesale prices for electronics, cosmetics, gifting, tools, and fragile accessories that need controlled positioning. This approach reduces item movement during storage and transit. It also helps brands maintain consistent in-box layouts across multiple SKUs.

These custom packaging inserts can be shaped for single units, multi-piece kits, and stackable assortments without wasting space. The smooth tray surface supports clean labeling and a more orderly unboxing flow for retail buyers. Packaging inserts for boxes also help reduce scuffs and micro-damage that happen when components rub against each other. This matters for glossy finishes, small parts, and sensitive accessories. A stable internal layout often lowers returns tied to in-transit shifting.

How Plastic Insert Trays Improve Product Control

Plastic insert trays provide defined cavities that keep items in place even when the outer carton is handled repeatedly. This structure helps prevent edge knocks and reduces pressure on delicate corners, especially for compact electronics and cosmetic containers. For brands selling bundles, the tray format also keeps each component easy to count and easy to present. This improves both packing speed and customer confidence when the box is opened. The result is more predictable product positioning across the full supply chain.

These inserts can be developed in clear, frosted, or tinted styles depending on your display goals. The tray wall height and cavity depth can be adjusted to suit bottles, jars, tubes, or mini devices. This supports a clean visual hierarchy where the product remains the focal point rather than loose filler. It also helps retailers keep shelf-ready kits consistent across reorders. A tidy internal structure can become a subtle brand signature over time.

Internal Protection Benefits

- Helps hold products in defined compartments

- Reduces surface friction between components

- Supports clean retail-facing arrangement

- Improves pack-out speed for kits

Layout And Handling Advantages

- Supports multi-piece sets with steady placement

- Helps reduce shifting during courier handling

- Keeps parts easier to count and verify

- Improves presentation for retail and gifting

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Compartment accuracy | Custom cavities for single or multi-item layouts | PET, RPET, PP, food-grade options | Clear, frosted, smooth | Anti-slip base textures | Electronics and beauty kits |

| Insert depth control | Shallow to deep pockets based on product height | Light to rigid gauges | Low-scuff coatings | Lift notches | Gift sets |

| Display alignment | Keeps products centered for clean unboxing | Clear and tinted plastics | Gloss and matte effects | Branding labels | Retail presentation |

| Shipping stability | Reduces movement inside outer cartons | Impact-resilient plastics | Smooth finishes | Edge supports | E-commerce |

Custom Plastic Inserts For Food And Fresh Packs

Custom plastic inserts for food help brands separate items cleanly and maintain a hygienic presentation inside sealed cartons and takeaway packs. Many food-focused businesses organize broader internal formats using Custom Product Options when they need reliable compartment systems across multiple product types. These inserts can support snacks, bakery assortments, confectionery trays, and sample kits where portion control and presentation matter. The structured layout also helps reduce contact between items. This improves cleanliness and reduces crushing risks during short-distance delivery.

These inserts can be designed to match portion sizes, multi-flavor assortments, and seasonal bundles without creating messy gaps. The material choice can align with cold items, room-temperature packs, and dry foods based on your usage plan. Brands offering Biodegradable to go alternatives sometimes pair plastic inserts with outer paper-based cartons for balanced protection and stable visuals. This keeps the food set neat for customers. It also helps staff assemble packs faster during peak hours.

Barrier Options And Hygienic Fit For Food Lines

Food inserts can be developed with smooth, easy-clean surfaces that support clean portion separation. This helps reduce cross-contact for mixed assortments and keeps delicate items from sticking or collapsing into each other. The cavity structure can be tuned for pastries, chocolates, mini desserts, or condiment sets based on depth and spacing needs. This supports clearer product visibility without opening individual inner wraps. The overall pack remains more confident and tidy at handover.

For bulk programs, consistent insert sizing helps standardize packing across multiple branches. This matters for brands that rely on uniform portion presentation across outlets and delivery platforms. Inserts can also include lift points that help customers remove items without touching adjacent pieces. This small detail improves both hygiene and user experience. When the internal structure is predictable, quality control becomes easier for staff.

Food Presentation Benefits

- Helps separate portions neatly inside cartons

- Supports cleaner handling for mixed assortments

- Reduces crushing for delicate items

- Improves consistency across branch packing

Service And Packing Advantages

- Supports structured food kits and sampler boxes

- Helps maintain portion identity in multi-flavor packs

- Improves speed during high-volume assembly

- Keeps sets more presentable on delivery

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Hygienic compartmenting | Clean separation for multi-item food sets | Food-grade PET, PP, RPET | Clear, smooth | Lift tabs | Bakery and confectionery |

| Portion control | Custom cavity sizes for exact counts | Light to medium gauges | Low-scuff | Divider ribs | Snack assortments |

| Temperature alignment | Suitable for chilled or ambient packs | Approved food-safe plastics | Neutral finishes | Moisture-resilient design | Fresh packs |

| Packing consistency | Standard sizes for repeatable workflows | Bulk-grade plastics | Smooth surfaces | Stack-friendly shapes | Multi-branch brands |

Custom Plastic Inserts Wholesale For Growing Brands

Custom plastic inserts wholesale programs help businesses maintain consistent internal packaging across large runs and repeated reorders. Many brands standardize procurement through Packaging Inserts Wholesale when they need dependable sizing, clean compartment accuracy, and stable material choices across multiple product categories. This approach supports electronics, cosmetics, gifting, lifestyle kits, and industrial small parts with the same organized in-box control. The result is a cleaner brand experience from warehouse to customer. It also reduces layout variation across expanding SKU families.

These inserts can be ordered as custom plastic inserts bulk formats for high-volume lines or custom plastic inserts no minimum for smaller launches and trial runs. Brands that want budget planning flexibility often compare custom plastic inserts cheap options based on material gauge and cavity complexity rather than sacrificing layout quality. This keeps new product rollouts manageable without breaking the packaging family look. Plastic insert trays also support easy assembly with consistent outer box footprints. This helps reduce operational friction for scaling brands.

Planning Bulk Inserts With Consistent Size Systems

Bulk planning works best when brands lock in a stable insert footprint and then adjust cavity layouts for different SKUs. This keeps outer cartons uniform while allowing internal variety across product types. It also helps reduce costs tied to frequent tooling changes. For multi-variant kits, the same tray base can be adapted with minor cavity updates. This supports faster refresh cycles for seasonal and limited-edition releases.

For logistics teams, standardized insert sizes simplify storage and picking. Flat or nested tray designs reduce warehouse clutter and help keep inventory categories clear. This is useful for brands that run subscription programs or bundled sets with predictable monthly output. When internal packaging is consistent, packing errors drop. Over time, this improves both efficiency and customer trust.

Wholesale Planning Benefits

- Supports consistent layouts across large runs

- Helps brands scale multi-SKU insert systems

- Keeps internal presentation uniform

- Reduces packing errors for kits

Growth And Inventory Advantages

- Supports repeatable tray footprints for new launches

- Helps reduce variation across reorders

- Improves warehouse organization for inserts

- Maintains cleaner unboxing for subscription lines

| Feature focus | Details | Material options | Surface finish | Extra elements | Typical usage |

|---|---|---|---|---|---|

| Volume flexibility | Supports bulk and smaller production needs | PET, RPET, PP | Clear, frosted | Standard footprints | Multi-SKU brands |

| Cost control | Material and cavity choices manage budgets | Light to heavy gauges | Smooth | Tooling reuse strategies | Growing product lines |

| Kit compatibility | Works with bundled and subscription sets | Impact-resilient plastics | Low-scuff | Modular cavity design | Lifestyle and tech kits |

| Storage efficiency | Nestable formats reduce space | Bulk-grade plastics | Neutral finishes | Stack-friendly edges | Warehouses |